Digital transformation

IBEJ with IDEA Software started the digitization process

read more...The benefits of effective steam trapping

Spirax Sarco and IBEJ are focused on helping our customers achieve process efficiency, increased production output and energy savings, and we know the importance of effective steam trap management in achieving this. A healthy steam trap population allows condensate to be removed from the steam system effectively which means it can be re-used. We call this ‘condensate recovery’ and it saves energy and cost in a number of different ways:

Reduced fuel costs

Normally, condensate will contain around 25% of the usable energy of the steam from which it came. Returning this to the boiler feedtank can save thousands of pounds per year in energy alone.

Energy saving

Condensate returned to the feedtank reduces the need for boiler blowdown, which is used to reduce the concentration of dissolved solids in the boiler. This therefore reduces the energy lost from the boiler during the blowdown process.

Reduced water charges

Returning and re-using condensate reduces the requirement for fresh replacement water.

Reduced chemical treatment costs

Re-using as much condensate as possible minimises the need for costly chemicals to treat raw water.

Reduced effluent costs

In many countries there are restrictions on releasing effluent at elevated temperatures so it must be cooled if discharged which incurs extra costs. Spirax Sarco are always on hand to advise you about the best ways to manage your steam system and to help ensure you continue to reap these benefits.

An introduction to steam traps

Mechanical steam traps

Maintaining optimum process performance

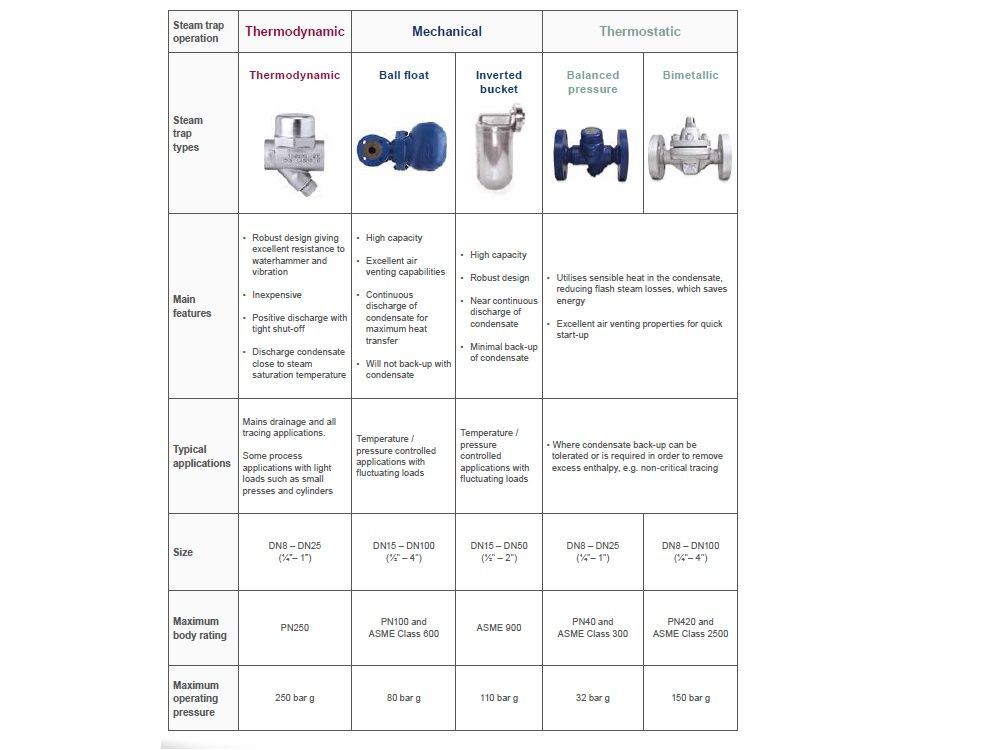

Mechanical steam traps are ideal for use on process applications where condensate must be removed as soon as it forms, to safeguard against temperature fluctuation which would lead to issues such as product spoilage and inadequate heating. Our mechanical steam trap range is adaptable to all applications where instantaneous removal of condensate is required. Each steam application has its own steam trap requirements. Selecting the right steam trap for your application could have a significant, positive impact on your process, potentially improving efficiency, reducing energy costs and giving you a safer working environment. For example: condensate must be removed promptly from a plant where maximum heat transfer is sought at all times. The presence of excess condensate in an item of heat transfer equipment will reduce its efficiency, preventing it from achieving its maximum rated output and may also reduce its service life. However; in other applications, it may be required to hold back the condensate to extract some of its heat and thus save on steam. Furthermore, by discharging condensate well below steam temperature, flash steam losses can be reduced or avoided altogether.

Thermodynamic steam traps

Maintaining optimum process performance

Thermodynamic steam traps are the best choice for steam mains drainage due to their simplicity, long life and robust construction. With a large condensate capacity for their size, the all stainless steel construction of our thermodynamic traps offer a high degree of resistance to corrosive condensate.

Mechanical steam traps

Maintaining optimum process performance

Mechanical steam traps are ideal for use on process applications where condensate must be removed as soon as it forms, to safeguard against temperature fluctuation which would lead to issues such as product spoilage and inadequate heating. Our mechanical steam trap range is adaptable to all applications where instantaneous removal of condensate is required.

Thermostatic steam traps

Utilising heat energy in condensate

For applications where it would be desirable to make use of the heat in the condensate such as sterilisation, a thermostatic steam trap is an ideal solution as it will not open until the condensate temperature drops below saturated steam temperature. This allows the heat in the condensate to be utilised before it is drained off which in turn reduces flash steam losses and can help to reduce energy costs Spirax Sarco and IBEJ offers a complete range of steam traps to ensure you can select the perfect trap for your application.

IBEJ with IDEA Software started the digitization process

read more...

Forums, fair, celebrations...all in honor of 70 years of Endress+Hauser

read more...

Do you know that moment, when you your plan doesn't work out, because of unplanned events? Watch our video and make sure this doesn't happen to you.

read more...